Farm Progress America, April 22, 2024

Farm Business Management

Farm Progress America, April 22, 2024Farm Progress America, April 22, 2024

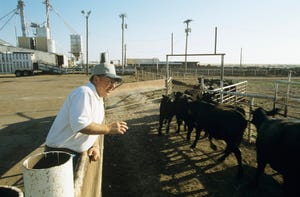

Mike Pearson takes a look at the Cattle on feed report released Friday after the markets closed for the day showed a much bigger drop in feedlot placements than analysts were anticipating.

Subscribe to Our Newsletters

BEEF Magazine is the source for beef production, management and market news.